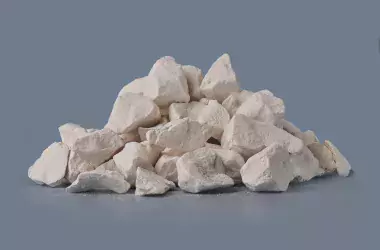

Limestone

What is Limestone?

Limestone,CaCO3 (calcium carbonate) is present in large quantities in the Earth's crust around the world. It is a sedimentary rock composed of the mineral calcite. It can be processed into a crushed, granulated, ground or milled product.

Some of the applications of limestone include agriculture, garden lime, lake and wetland liming, as well as the production of paper, paint, glass, asphalt, bricks, concrete and metals.

Discover all products using limestone

Contact our experts

You want to know more about Limestone?

Contact us!