Non Ferrous Metallurgical Processing

Non-ferrous metallurgical processing

Lithium

Lime is used during the processing of solution brines and mineral ores to produce lithium carbonate and lithium hydroxide.

Copper

Lime is used in the metallurgical processing of different copper ore types, ranging from flotation of copper sulphide minerals to leaching of copper oxides by acid lixiviants.

Gold

Gold is contained in many different ore types, each requiring a specific processing route for optimal gold recovery.

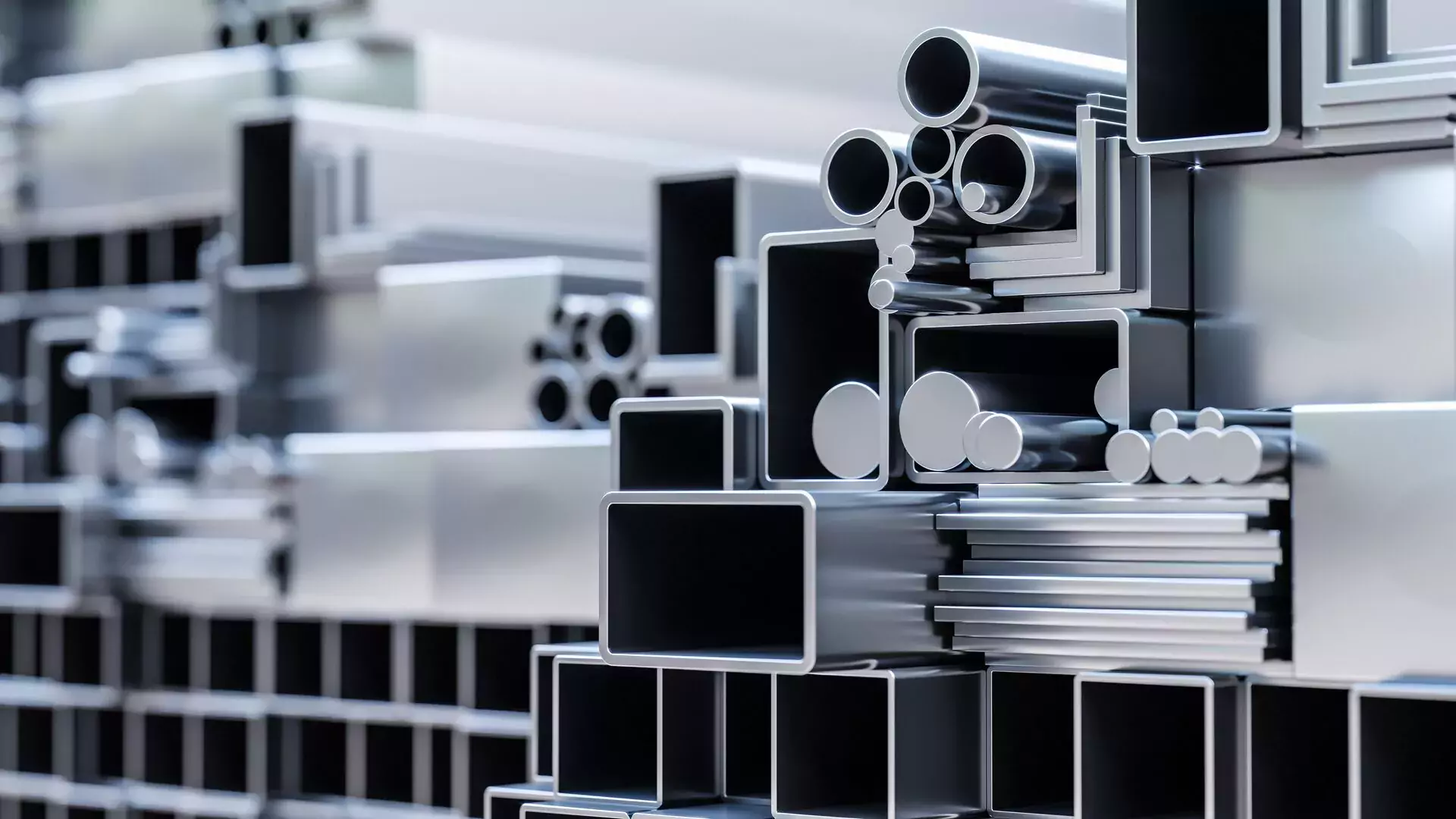

Alumina

Lime is used in various process steps during the refining process to convert bauxite ore into alumina (aluminium oxide) product in high purity powder form.

Others

Lime is used in a wide range of other applications from the mining and extractive metallurgy industries.