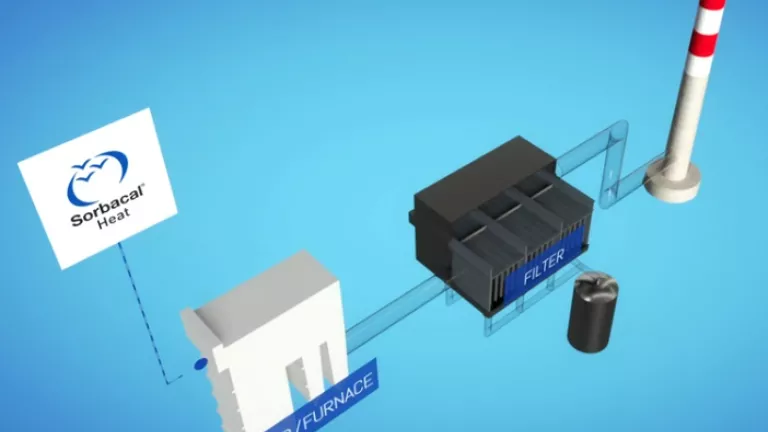

Furnace Sorbent Injection (FSI)

What is Furnace Sorbent Injection (FSI) process?

FSI technology involves the injection of sorbents directly into the furnace/boiler or mixed with the fuel. This technology is mainly used in Waste-to-Energy and biomass plants.

The field of action of the sorbents goes from acid gas emission control (like SO2 peaks or HF emission control) to the reduction of the fouling and slagging issues that take place in the furnace/boiler. The product can also have a dual effect.

Under FSI conditions, the acid gas capture (SO2 removal) is very efficient because of the high reaction temperature and the absence of competitive reaction with CO2.

The injection of sorbents also reduces the slagging/fouling issues by increasing the melting temperature of the boiler ash.

Benefits

The benefits vary depending on the sorbent used. Our experts will analyse your unique situation and tailor a specific solution for you. Our solution will include recommendations on the best injection points in the furnace/boiler, best sorbent, trial test equipment and best technologies to inject our sorbents.

Depending on the sorbent used, you will have the following benefits:

Acidic gas removal:

- Improved SOx capture

- Debottlenecked Flue Gas Treatment (FGT)

- Savings on incumbent FGT reagent

- Reduced residue disposal costs.

Anti-slagging/Antifouling:

- Higher capacity of heat transfer

- Increased waste throughput

- Reduced maintenance and cleaning costs.

Lhoist product range dedicated to FSI