Our products & ranges

Our products pave the way towards a better tomorrow.

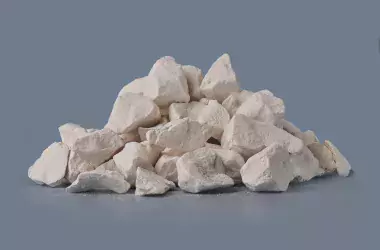

Bringing purity and efficiency to the specific needs of our customers, our solutions are used in a wide variety of traditional and emerging applications due to their unique chemical and physical properties.

Contact our experts

You want more information about what we offer at Lhoist or about our services?

Contact us!