Mercury abatement on a coal combustion plant

Czech Republic

The challenge

Due to the strict European air regulations, large coal energetic units face new issue with regards to mercury emissions. They must decrease them under determined limits using one of the best available techniques (BAT) published in BREF documents.

Selective catalytic methods, carbon-based sorbents, such as activated carbon, halogens admixtures or a fuel treatment before its combustion are potential solutions for the abatement of mercury emissions.

However, every solution requests cost and it is necessary to find the optimum and most cost effective one. A Czech large coal combustion plant (>300 MWth) decided to co-operate with Lhoist and find the optimum way for their arrangement.

The Lhoist solution

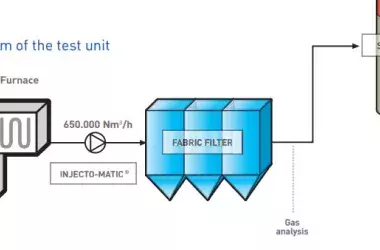

The dry sorbent injection of special sorbents with different compositions was proposed and selected encompassing the Injecto-Matic dosing machine. Those sorbents were dosed into the duct in front of the fabric filter. Mercury concentrations were measured continuously after the fabric filter by a dedicated analyzer.

To determine the efficiency of sorbents, tests were carried out under different loads of the boiler and configurations of dosage with the same lignite quality.

The tests compared three sorbents:

- Sorbacal® Micro 2420

- Natural zeolite

- Sorbacal Micro 6375

Each of them represented a different group of sorbents with various capabilities to the mercury capture.

The benefits

Tests carried out demonstrated the following sorbent efficiency on the mercury removal:

- Sorbacal® Micro 6375 > Sorbacal Micro 2420 > natural zeolite

- Targeted limit of 7 μg/Nm3 was met with all tested sorbents.

In addition, Sorbacal® Micro 6375 offered specific advantages:

- much lower sorbent consumption in comparison with other ones

- it is non-flammable and non-explosive

- it is tailor-made according to key parameters at the client