The challenge

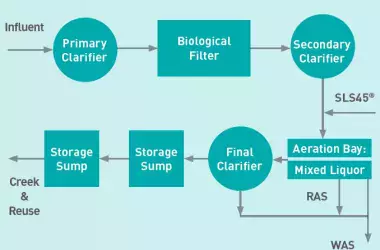

The customer is a wastewater reclamation plant located in southern California which treats approximately 2.2-3.6 MGD of wastewater for cooling towers, creek replenishment, and water reuse. The incoming wastewater delivered to the treatment process typically has 50-55 ppm of ammonia, alkalinity levels of approximately 300 ppm, and varying influent pH between 7.4-7.8 depending on the water source.

Historically, the wastewater was treated for alkalinity, ammonia, and pH adjustment by addition of magnesium hydroxide and caustic soda (NaOH). The process was inefficient with magnesium hydroxide slurry leading to high sludge production and the effluent not consistently meeting the required water quality parameters.

Meeting the customers needs

The customer requested an evaluation of an alternative reagent, specifically a high quality liquid lime reagent that could:

- Replace the current inefficient magnesium hydroxide and caustic soda used for alkalinity and pH adjustment and for ammonia removal in the aeration basin;

- Achieve consistent outlet pH and avoid wide fluctuations;

- Eliminate low alkalinity events that could translate into ammonia spikes;

- Improve overall ammonia removal.

The Lhoist solution

Lhoist North America recommended implementing SLS45 to meet the customer’s needs. SLS45 is a homogeneous liquid lime slurry with high percentsolids and fine particle size, thus reliably delivering high pH adjustment performance.

To achieve the same pH adjustment, SLS45 requires less product than magnesium hydroxide due to its high reactivity, and a similar amount to caustic soda. SLS45 is easy-to-use and provides better pH control performance than regular magnesium hydroxide slurry and similar pH control performance to caustic soda. SLS45 is free flowing and is not prone to sedimentation and buildup, thus minimizing maintenance frequency.

The high reactivity and ease-of-use of calciumbased SLS45 also helps reduce sludge production and improves dewatering efficiency to further lower treatment costs.

The benefits

The long-term trial with SLS45 was considered successful and yielded the following benefits:

- Meeting the pH requirement of 7.2-7.4 in the clarifier outlet;

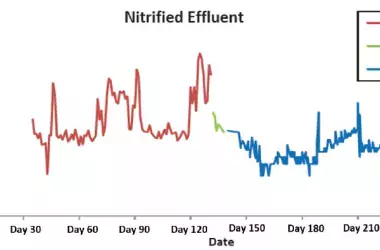

- Consistently achieving the alkalinity > 140 mg/L target in the clarifier outlet, while historical data showed inconsistencies with some low alkalinity events;

- Improved ammonia removal by 92% vs. the existing treatment and reliably meeting the target ammonia < 0.1 mg/L in the clarifier outlet;

- Enhanced total suspended solids (TSS) removal by 29% vs. the existing treatment in the final clarifier outlet ;

- Elimination of handling issues associated with magnesium hydroxide slurry;

- Avoiding use of caustic soda, and the associated hazards.

Conclusion

SLS45 provides consistency in solid content as well as particle size, thus delivering consistently high alkalinity, ammonia, and pH adjustment performance. Ammonia removal was improved by 92% and TSS enhanced by 29%.

The alkalinity in the nitrified effluent was consistently higher with fewer fluctuations when using SLS45. Overall, the key parameters identified during this field trial improved greatly when using SLS45 in place of previous alkalis. The positive results of the trial led to the customer converting to SLS45.

Contact our experts