North America

The challenge

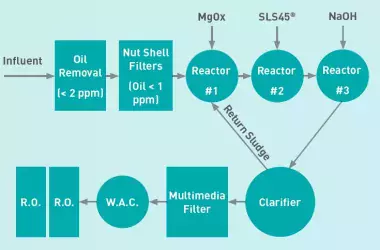

The customer is an oil and gas company located in California operating an oilfield that generates approximately 2.5 MGD of process water that requires softening as well as silica and hydrocarbons removal.

Historically, the water was treated for hardness removal using a dilute lime slurry (made from hydrated lime) to a pH target of 9.5, followed by caustic soda (NaOH) until a pH target of 10.5, as well as magnesium oxide (MgOx) for silica precipitation. This softening process was inefficient and led to increased sludge production and associated disposal costs.

The customer was interested in evaluating the performance of a higher quality liquid lime reagent that could:

- Replace the current inefficient lime slurry to alleviate pumping and dosing issues, thereby reducing operator time required to maintain the system;

- Decrease the turbidity of the clarifier outlet;

- Reduce the caustic soda usage for the warm lime softening and silica removal process;

- Reduce fluctuations in reagent costs as well as overall treatment costs;

- Lower sludge production and associated disposal costs.

The Lhoist solution

Lhoist North America recommended implementing SLS45 to more effectively soften the process water while reducing overall costs. The dissolution of SLS45 offers quick release of calcium and hydroxyl ions for rapid softening while avoiding over-dosing.

SLS45 is free-flowing and is not conducive to sedimentation and buildup thus reducing maintenance frequency.

The product reacts very quickly and very completely. This improves control over the process, minimizes overfeed of reagent, reduces the amount of sludge produced, and improves sludge dewatering efficiency.

The benefits

The trial of SLS45 was a success. The pH could be increased to over 10.5 in a similar fashion to caustic soda.

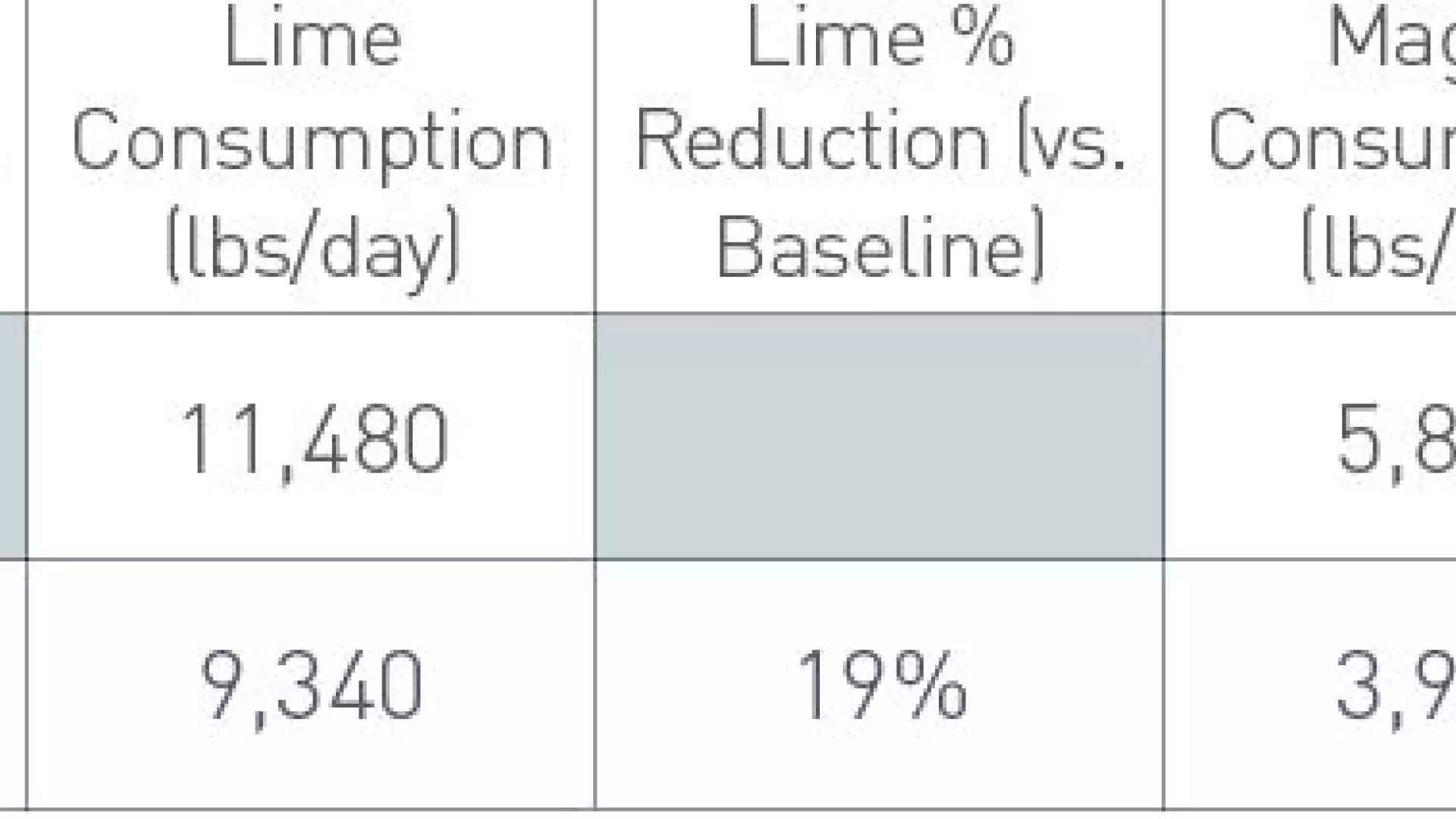

SLS45 usage reduced the overall chemical consumption by almost 10,000 lbs/day (expressed on a dry basis) as shown in the following table. This resulted in $432,000, or 22% savings in yearly chemical costs alone.

The trial with SLS45 yielded the following benefits:

- Replacement of all the regular lime slurry and reduction of 61% of the caustic soda used for pH

- adjustment;

- Reduction of fluctuations in reagent use;

- Minimization of pH fluctuations: from ±1 pH during the baseline, to ±0.5 pH with SLS45;

- Drastic decrease of clarifier outlet turbidity: with SLS45®, turbidity was lower than 1 NTU 75% of the time, while it could reach the same results just 28% of the time when using regular lime slurry;

- Reduction of sludge production by 2.2 tons/day and annual savings of $24,000 in sludge disposal costs.

Conclusion

SLS45 provides consistency in dosing rate as well as particle size, thus delivering consistently high pH adjustment performance. It is easy-to-use and provides better pH control performance than regular lime slurry and similar pH control performance to caustic soda.

There are many benefits to using SLS45 including reduced chemical costs, reduced turbidity, improved solids dewatering, less sludge production, and improved handling. All these improvements saved the oil company in this case study over $456,000 per year.

Contact our experts